Top 7 Industries Using Burnishing Tools for Precision Components

- Subudhha W

- Dec 16, 2025

- 2 min read

In precision manufacturing, surface finish, dimensional accuracy, and component life play a crucial role. Burnishing is a highly effective finishing process that improves surface quality without material removal, making it faster and more economical than grinding or honing.

Because of these benefits, burnishing tools are widely used across multiple industries. Below are the top 7 industries using burnishing tools for precision components.

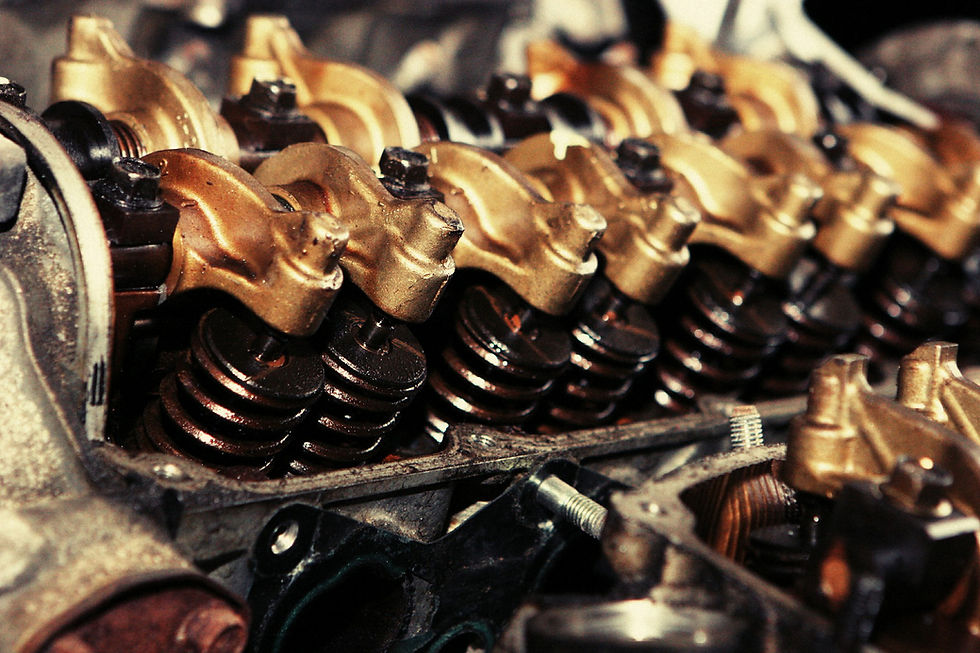

1. Automotive Industry

The automotive sector uses burnishing tools for high-volume precision parts such as:

Engine shafts

Gear and transmission bores

Steering and suspension components

Benefits: Improved surface finish, higher fatigue strength, reduced wear, and better oil retention.

2. Aerospace Industry

Aerospace components demand maximum reliability and strength.

Applications include:Hydraulic cylinders, actuator housings, landing gear parts, and shafts.

Benefits: Enhanced fatigue life, compressive residual stress, and damage-free finishing.

3. Hydraulic & Pneumatic Industry

Smooth internal surfaces are critical for leak-free fluid systems.

Common parts:Hydraulic cylinders, valve bodies, pump housings.

Benefits: Reduced friction, improved sealing, longer service life.

4. Oil & Gas Industry

Burnishing is used for components operating under high pressure and harsh conditions.

Applications:Valve bores, pump shafts, sleeves.

Benefits: Better wear resistance, reduced surface cracks, improved durability.

5. Bearing & Power Transmission Industry

This industry requires tight tolerances and smooth contact surfaces.

Burnished components:Bearing races, collars, shafts, gear bores.

Benefits: Higher load capacity, reduced noise, longer bearing life.

6. Machine Tool & General Engineering

Machine tool manufacturers use burnishing to enhance performance and productivity.

Applications:Spindles, guideways, precision shafts.

Benefits: Improved accuracy, reduced finishing time, better wear resistance.

7. Medical Equipment Industry

Medical components demand ultra-smooth and hygienic surfaces.

Applications:Surgical tool parts, medical-grade shafts, precision housings.

Benefits: Superior surface finish, improved cleanliness, repeatable precision.

Why Choose Burnishing Tools?

Burnishing tools offer:

Excellent surface finish

Increased component strength

Faster cycle times

Cost-effective finishing

At Mech-India, we manufacture standard and customized burnishing tools for OD, ID, taper, blind hole, and special applications to meet diverse industry needs.

From automotive to medical manufacturing, burnishing tools play a vital role in producing high-quality precision components. Choosing the right burnishing solution helps improve performance, durability, and productivity.

📩 Contact Mech-India today to discuss your burnishing tool requirements.

_ed.png)

Comments